second hand 1880mm fluting corrugated paper making machine

Keyword:

second hand 1880mm fluting corrugated paper making machine

Category:

Mailbox:

Description

Product Description

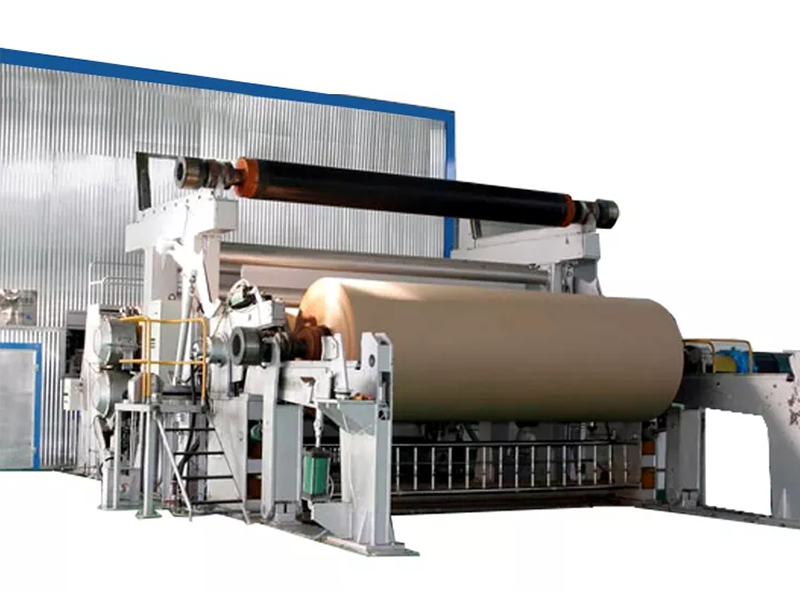

Secondhand 1880mm fluting corrugated paper making machine

Product details

|

Working speed |

60-350m/min |

|

Dairy capacity |

80-100T/D |

|

Output paper |

kraft paper, cardboard paper rolls |

|

Paper width |

1092-4200mm |

|

Raw material |

waste paper, virgin pulp, whest straw and rice straw |

|

PLC and motor brand |

ABB, Siemens, Ormon,etc, optional |

|

material |

SS, cast iron, carbon steel |

|

Drive way |

Frequency convertor |

|

Application |

Paper Industry |

|

Color |

Customized Color |

|

Product Keywords |

1880mm fluting paper corrugated paper machine,1092 small corrugated paper making machine |

This machine can use different kinds of waste paper, recycled old carton box, wheat or rice straw, sugarcane bagasse, virgin pulp,cotton, wood,etc as material to make kraft paper, corrugated/liner paper,finished product can be jumbo paper roll.

It include following section:

1.Pulp making section;

2.Paper making section;

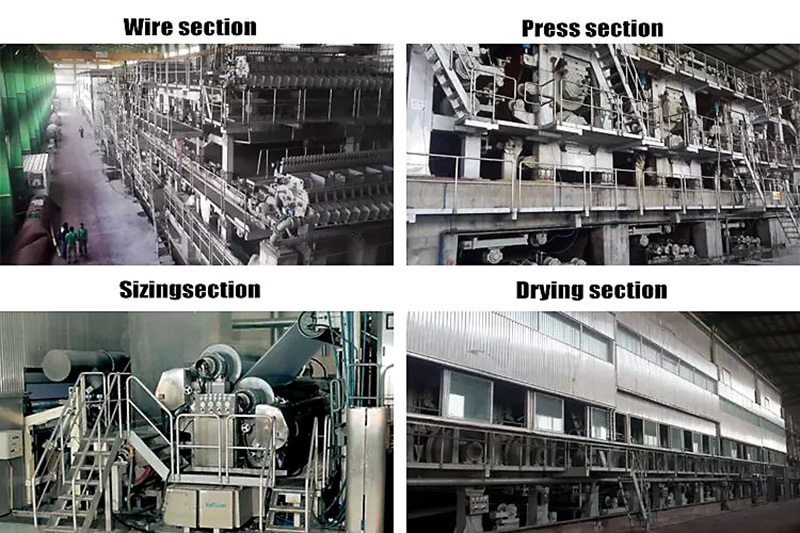

Part of paper making lines

1) Wire section:

(1)Total two type: cylinder mould usually used for small capacity paper mill, and fourdrinier wire for little big capacity.

(2) Fourdrinier table length is usually between 13m and 24m.(decided by working speed).

(3) It can select open-type headbox when the working speed is less than the 250m/min;

2). Press Section:

(1) The press consists of a vacuum suction device, four rollers twin press and one main press.

(2) Four rollers twin press specially suit for making a4 copy paper, newsprinting paper,culture paper and writing paper.

(3 )The main press can improve press nip width dewatering wet sheet strength and finished paper density.

3).Dryer section:

(1) It usually uses several dryer cylinder groups with the diameter of Φ1500mm or Φ1800mm. drive: closed gear box each dryer group single drive or single gear box each dryer group multi-points drive.

(2) When wet paper enters into dryer section, it can select different leading way and paper orientation according to PM working speed, production basis weight and pulp impurity.

3.Paper converting section;

Related products

Get a Free Quote

Contact Us

Add:300 meters south of the turntable in Ge Village, Baixiang Town, Qinyang , Henan,China

WeChat:WU18520049193

Copyright Qinyang Shengfeng Paper Making Machinery Co., Ltd. This site already supports ipv6